In the world of mechanical security, innovation has continuously evolved to meet the demands for better protection, higher durability, and smarter locking mechanisms. One standout example is the tubular cam lock, a design known for its distinctive circular keyway and advanced pin configuration. Also referred to as a circle pin tumbler lock, radial lock, or Ace lock, this mechanism has earned its reputation as one of the most secure and efficient lock types in commercial and industrial environments.

Tubular cam locks are widely used in vending machines, kiosks, ATMs, cabinets, lockers, mailboxes, and industrial equipment—essentially, anywhere that requires both security and quick accessibility. What sets them apart is their circular design, which makes them more resistant to conventional picking methods compared to traditional flat-key pin tumbler locks.

This article explores how tubular cam locks work, their internal mechanisms, key features, picking resistance, and why they continue to play a vital role in modern locking systems.

A tubular cam lock is a specialized type of key-operated lock designed with a circular keyway and radially arranged pins. Unlike the linear arrangement found in conventional locks, the pins in a tubular lock form a circle around the keyhole. This radial layout enhances security and makes unauthorized tampering significantly more difficult.

The design concept originated in the mid-20th century and was popularized by Ace Lock Corporation, which is why the lock is sometimes referred to as an “Ace lock.” The fundamental principle remains the same today: the lock’s structure is engineered for resilience, precision, and compactness, making it a preferred choice for applications where reliability and tamper resistance are essential.

Despite its seemingly complex design, the tubular cam lock operates on the same basic principle as a standard pin tumbler lock—alignment of pins to create a shear line that allows the lock to turn. However, the geometry of a tubular lock provides a much higher level of protection.

Here’s a detailed breakdown of how it works:

Inside the lock cylinder, there are typically 7, 8, or 10 spring-loaded pins arranged radially around the center. Each pin stack consists of a driver pin and a key pin, just like in a standard tumbler system. These pins are pressed inward toward the core by springs.

The tubular key—a cylindrical key with a hollow center and notches around its perimeter—is inserted into the circular keyway. Each notch corresponds to a specific pin within the lock.

As the key slides in, its notches push the pins to precise depths. When all the pins align with the shear line (the gap between the plug and the housing), the lock’s plug can rotate freely. This alignment is what makes the lock operable.

Once the shear line is achieved, the user can rotate the key to engage or disengage the cam mechanism attached to the back of the lock. This cam movement is what physically locks or unlocks the device, securing the door, drawer, or equipment it’s attached to.

To truly appreciate the ingenuity of the tubular cam lock, it helps to visualize its internal components.

The lock features a solid central cylinder (or plug) surrounded by a metal housing. The keyway is circular with a notch or index groove that ensures the key is inserted in the correct orientation.

When viewed from the front, you’ll notice several small holes around the circle—these are the pin chambers. Inside, each chamber contains a driver pin, key pin, and spring. The unique part is that these pins move horizontally rather than vertically, creating a circular motion instead of a straight line.

The tubular key complements this design perfectly. It has a cylindrical body with grooves along its sides and a hollow center to fit over the lock’s central post. At the tip of the key are cuts of varying depths, each corresponding to a specific pin height.

The result is a compact yet robust mechanism capable of providing smooth, precise operation while maintaining a high resistance to tampering or forced entry.

Tubular cam locks are versatile and used across multiple industries where security, durability, and ease of use are key requirements. Here are some of the most common applications:

Vending Machines: To prevent unauthorized access to cash boxes or inventory.

ATMs and Kiosks: Ensures security for financial and transactional hardware.

Lockers and Cabinets: Ideal for gym lockers, mailboxes, and storage cabinets.

Gaming and Ticket Machines: Used to secure coin hoppers and cash compartments.

Industrial Enclosures: Protects electrical panels, telecom cabinets, and power distribution boxes.

Bicycle Locks: The compact tubular design is often integrated into high-security bike locks.

These use cases highlight how the tubular cam lock balances accessibility and protection, making it one of the most practical security devices available today.

While no lock is completely pick-proof, tubular cam locks are notoriously more difficult to pick than standard tumbler locks due to their radial configuration.

There are generally three recognized methods for attempting to pick a tubular cam lock:

This traditional technique involves individually setting each pin using specialized tools. However, because of the circular pin layout, SPP is time-consuming and challenging. The picker must repack the lock after every quarter turn, which can quickly become tedious.

A more common approach uses a tubular lock pick, which is designed specifically for circular locks. The tool contains a set of “needles” arranged in a circle to match the pin layout. Each needle adjusts independently to find the correct pin depth.

Before use, the picker calibrates the tool, inserts it into the lock, and applies gentle rotational pressure. If successful, the tool simultaneously picks and decodes the lock, allowing the user to create a duplicate key.

However, this method still requires skill, as incorrect calibration or uneven pressure can easily bend the tool’s delicate needles.

In rare cases, skilled locksmiths use impressioning techniques to decode the key bitting without disassembling the lock. This involves inserting a blank key and studying the pin marks left behind, which reveal the correct depths.

Overall, tubular cam locks are significantly more resistant to casual picking attempts, making them a reliable choice for securing valuable equipment and restricted areas.

Tubular cam locks provide several design and performance advantages that make them stand out among other mechanical locks:

The defining feature of a tubular lock is its round keyway, which corresponds perfectly to the tubular key’s cylindrical shape. This design prevents standard flat keys or tools from being inserted, instantly deterring most common lockpicking methods.

With pins arranged in a circle rather than a straight line, manipulating them becomes far more complex. This radial pin configuration enhances both security and precision.

Tubular cam locks are built from robust materials such as stainless steel, brass, or zinc alloy, ensuring a long operational life even under frequent use. Their design minimizes wear and tear, making them ideal for commercial applications.

Thanks to the alignment of circular pins and balanced key insertion, tubular cam locks provide smooth and reliable rotation with minimal friction. This feature is especially valuable in machines that require consistent daily operation.

Because of their structural complexity and limited access points, tubular locks are highly resistant to forced entry, drilling, or bumping attacks. Some advanced models even include anti-drill pins and hardened steel housings for additional protection.

Their small form factor allows installation in tight spaces without compromising functionality. Manufacturers often produce them in various lengths and cam styles to fit diverse applications.

Traditional pin tumbler locks are still widely used, but tubular locks offer distinct advantages:

|

Feature |

Traditional Pin Tumbler Lock |

Tubular Cam Lock |

|

Keyway Shape |

Flat or rectangular |

Circular |

|

Pin Layout |

Linear |

Radial |

|

Picking Resistance |

Moderate |

High |

|

Key Design |

Flat blade |

Tubular cylinder |

|

Durability |

Average |

Excellent |

|

Typical Applications |

Residential doors |

Industrial equipment, vending, ATMs |

The circular mechanism of tubular locks not only improves tamper resistance but also enhances reliability in high-use environments where conventional locks might wear out quickly.

Installing a tubular cam lock is straightforward and typically requires only a few steps:

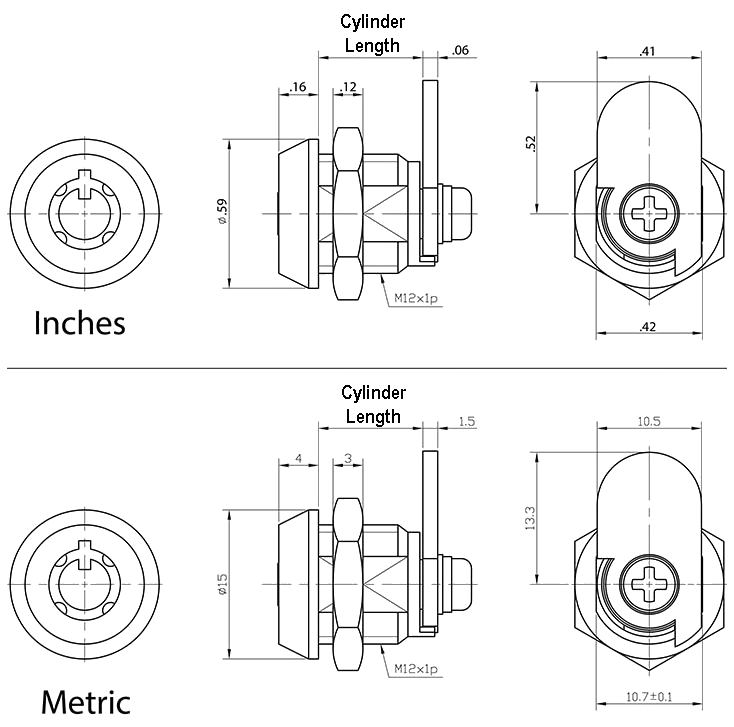

Measure the Mounting Hole: Ensure that the panel hole matches the lock’s diameter, usually 19mm or 22mm.

Insert the Lock Body: Slide the cylinder into the mounting hole from the front.

Secure with Nut: Tighten the locking nut from the rear to hold the lock in place.

Attach the Cam: Fix the cam arm to the back of the cylinder using a screw or retaining clip.

Test the Rotation: Insert the key and rotate it to verify smooth operation.

For maintenance, occasional lubrication with graphite powder or a silicone-based lubricant helps prevent dust accumulation and ensures smooth movement. Regular inspection of the cam and retaining parts is also advised, especially for outdoor installations.

Advancements in security technology have influenced even traditional mechanical systems. Today’s tubular cam locks are often integrated with electronic or smart features, including:

Keyless Tubular Locks: Incorporating electronic sensors that recognize encoded keys.

Hybrid Locks: Combining mechanical tubular designs with Bluetooth or RFID control.

Anti-drill and Anti-pick Designs: Enhanced materials and pin configurations for superior resistance.

Custom Branding and Keying Systems: Allowing manufacturers and clients to specify key codes, logo engravings, or unique cam designs for OEM applications.

These innovations show that tubular locks remain relevant in the digital age, bridging the gap between mechanical reliability and smart functionality.

The tubular cam lock is a timeless example of mechanical ingenuity and practical security. Its circular design, radial pin system, and robust construction make it one of the most tamper-resistant and durable locks available.

From vending machines to industrial control panels, this lock continues to protect essential equipment around the world. Its ability to combine simplicity of operation with high-level security explains why it remains a trusted choice across decades of innovation.

Whether you’re a manufacturer, security engineer, or technician, understanding the principles and benefits of tubular cam locks is key to designing and maintaining reliable access control systems for modern applications.